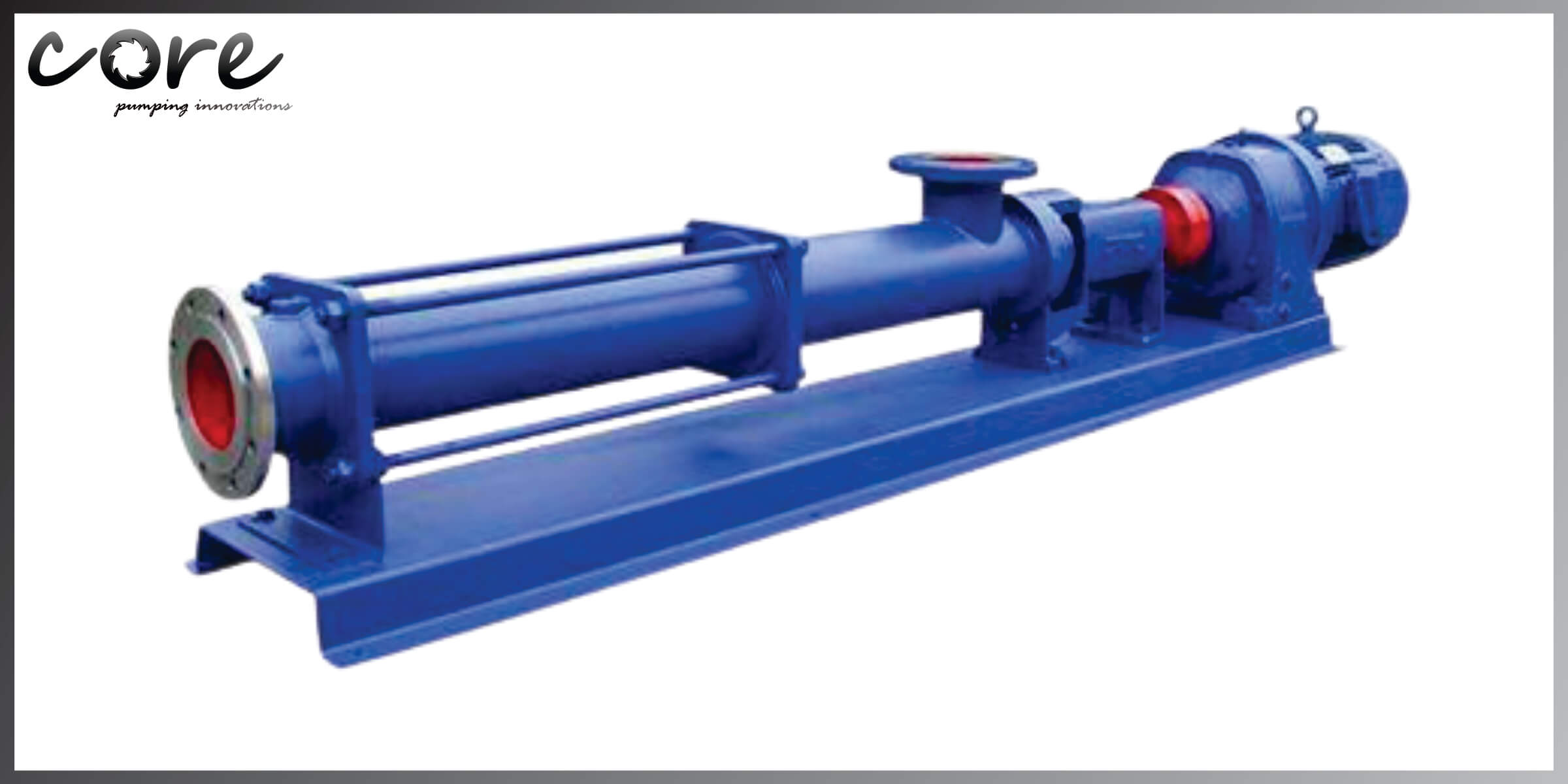

Core Pumps make CPC Series positive displacement / Progressive Cavity, helical screw Pumps coupled directly through geared motor/ V-Belt Systems.

These pumps are ideal when pumping thick sludges, pastes and it’s food grade material makes it ideal to be wed in many industries such as chemical, Beverages, fruits & vegetables processing plant, pulp & paper, mines, ceramics and sugar mills etc.

APPLICATIONS

• Sewage & Waste Water Treatment Plant

• Chemical, Dye, Paint & Petrochemicals

• Beverages, Breweries & Winners

• Dairy, Sweets & Confectioneries

• Cosmetics & Pharmaceuticals

• Sugar Mills

• Ceramic & Refectories

• Steel Plant

• Veg Oil & Vanaspti Plant

• Fruit & Vegetable Process

• Paper & Pulp

• Mines

• Explosive

FEATURES

ENERGY SAVINGS The high efficiency hydraulics of the screw pump are optimized by computational fluid dynamics calculations which create an ideal flow of pumped liquid. Rotor turns inside a resilient stator and thus generates low noise level around 75db. This reduces both life cycle costs and energy demand, which gives the pump values well above international standards. SELF-PRIMING & DETACHABLE BEARING HOUSING inherently self-priming can work on snore and does not require gate & check valve in progressive cavity pumps fluids can be pumped with no contamination. REDUCED WEAR An assortment of smart design features and materials that extend the life of the screw pump and its components, for example non clogging application it can handles solids in suspension or mixture containing high percentage of solids. Thanks to its very low internal velocity reduces wear due to erosion and corrosion. Low rpm’s & Flow is metered uniform and steady with minimum pulsation. The ultimate result is a more efficient, more effective operation. EASY MAINTENANCE Easily service the CPC Pump, its smart, simple, modular design. pumps perform with equal efficiency in either direction due to reversible rotation capabilities. The bearing at the drive side, the mechanical seal , bearing housing seperate are all easily accessible without having to remove the pump from the piping system. the pump’s modularity minimizes the number of parts needed to cover the complete performance range, which simplifies assembly and streamlines spare parts management.

PERFORMANCE DATA

• Capacity : Up to 150 M³/Hr.

• Pressure : Up to 6 Bar

• Temperature : Up to 140°C

• Viscosity : Up to 10,00,000 CST

• Total suction lift up to 7 mt.

• Continuous duty